As one of the core components of power transformers and motors, ei lamination play a key role. Its optimal design and fabrication are crucial for the efficiency and reliability of power transmission.

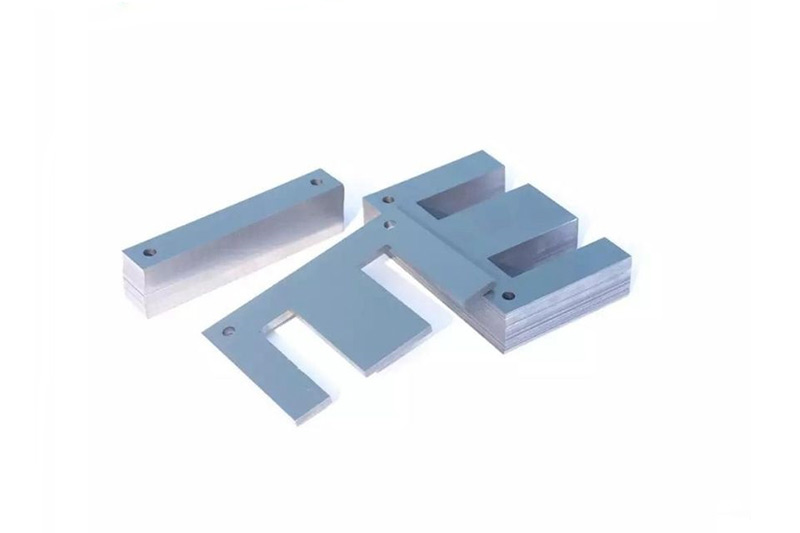

1. Definition and structure of ei lamination

The EI iron-plated sheet is composed of two overlapping electromagnet chips, and the shape is “E” and “I”. It is made of high-quality silicon steel material, which has high magnetic permeability and low hysteresis loss, making it ideal for manufacturing electromagnetic devices. The surface of the iron-plated sheet is treated with an insulating coating to prevent current leakage and magnetic loss.

2. Application of ei lamination

EI iron-plated sheets are widely used in power transformers and motors. In power transformers, it is used to construct a magnetic circuit by winding an induction coil around an iron core. This can improve the transmission efficiency of the magnetic flux, reduce energy loss, and ensure the working stability of the power transformer. In motors, EI-plated iron sheets are used to manufacture stators and rotors to generate magnetic fields, thereby converting electrical energy into mechanical energy.

3. The effect of ei lamination on power transmission

The design and manufacture of EI iron-plated sheets have a significant impact on the efficiency and reliability of power transmission. First of all, high-quality silicon steel material has excellent magnetic permeability, which can effectively control the transmission of magnetic flux and reduce magnetic loss. Secondly, the structural design of the iron-plated sheet is reasonable, which can reduce the resistance of the induction coil and the phenomenon of magnetic flux leakage, and improve the utilization rate of electric energy. In addition, the existence of the insulating coating can prevent current leakage and magnetic loss, and enhance the insulation performance and safety of the equipment.