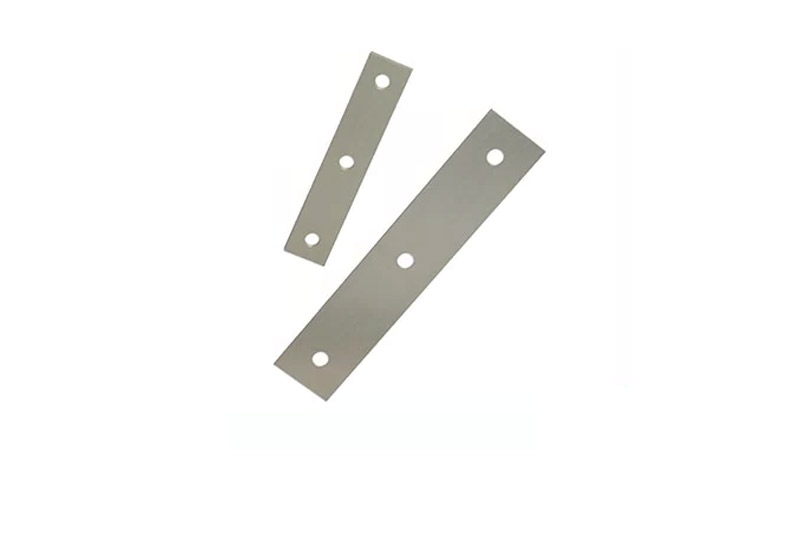

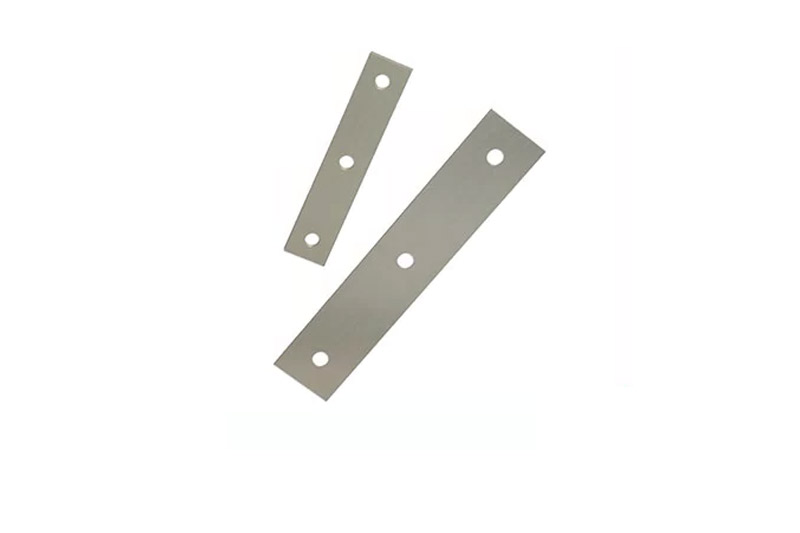

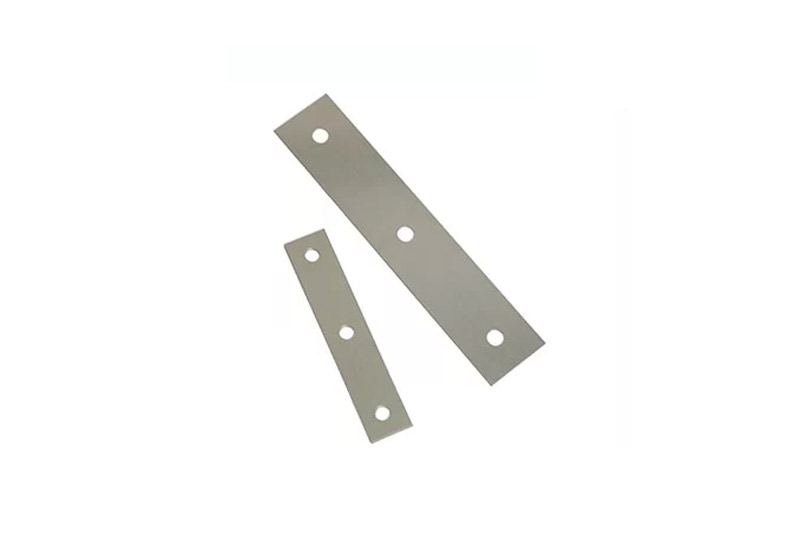

READY-CORE laminations

READY-CORE laminations

The separate, latchable sheets of the EI range are characterised, as a special range, by their integrated latching mechanism which in turn allows for particularly quick and economical processing. Separate, latchable sheets do not have to be nested reciprocally but can rather be slid into the coil body from either side in packages and snapped together. We offer processing machines (tamping machine type 300) for this. The usual DIN standardised EI coil bodies can be used.

READY-CORE laminations Features

Scope

Control Transformer

Power Transformer

Ballast Resistor

READY-CORE laminations Table

| TYPE | length | width | high | ø | other |

| 38×190 | 190 | 38 | 3 | 10 | |

| 38×190 | 190 | 38 | 3 | 12 | |

| 45×225 | 225 | 45 | 3 | 10 | |

| 45×225 | 225 | 45 | 3 | 12 | |

| 38×95 | 95 | 38 | 2 | 4 | |

| 40×40 | 40 | 40 | |||

| 38×40 | 40 | 38 | |||

| 40×200 | 200 | 40 | 3 | 10 | |

| 40×200 | 200 | 40 | 3 | 11 | |

| 30×90 | 90 | 30 | |||

| 30×150 | 150 | 20 | 3 | 8 | |

| 35×170 | 170 | 35 | 3 | 10 | |

| 35×197 | 197 | 35 | 3 | 10 | |

| 30×170 | 170 | 30 | 3 | 10 | |

| 30×175 | 175 | 30 | 3 | 10 | |

| EIB114 T=2.0 | 114 | 19 | 4 | 7 | Need mold cost |

| EIB114 T=2.6 | 114 | 19 | 4 | 7 | Need mold cost |

| EIB114 T=3.0 | 114 | 19 | 4 | 7 | Need mold cost |

| 35×107 | 107 | 35 | |||

| 35×143 | 143 | 35 |

•Determine core dimensions from transformer specs and winding/bobbin size.

•Choose high stacking factor for maximum winding space and efficiency.

•Opt for low core loss for reduced heat generation and better energy efficiency.

•Optimize core size for desired performance characteristics.

•Consider manufacturing limitations and cost when selecting core size.