UI lamination

UI lamination

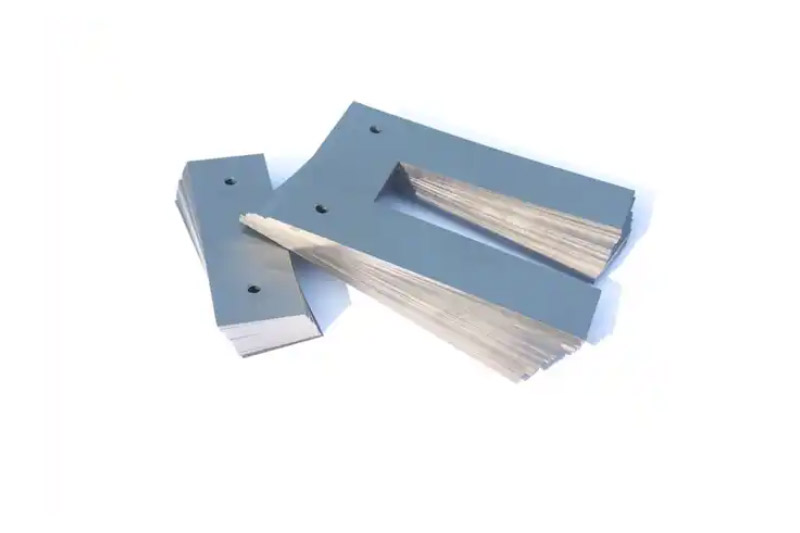

UI lamination cores are used as an alternative to EI lamination cores for single-phase transformers. They allow for the construction of slimmer transformers. In transformers with UI sheets, both arms of the U sheet bear a coil body each. UI sheets cannot be welded since the cut edges of the U and I sheets lie within the coil body. They therefore have to be reciprocally nested. This can be done manually or with a nesting machine.

UI lamination Features

Scope

Control Transformer

Power Transformer

Ballast Resistor

FEEDBACK

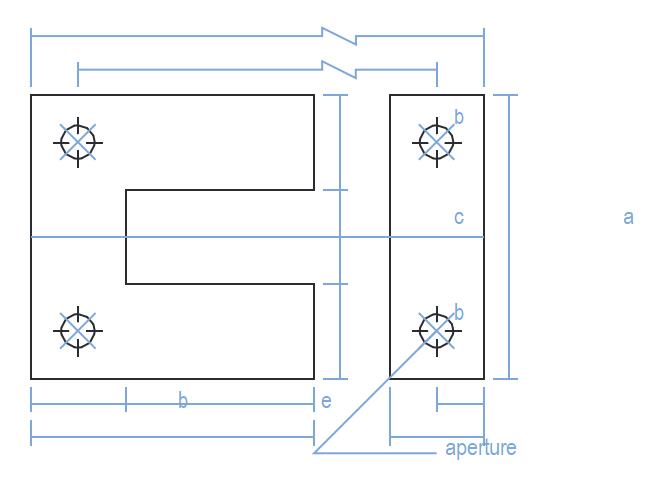

UI-lamination Table

TYPE | a | b | c | d | e | f | holes | ø | Gap |

UI-16 | 48 | 16 | 16 |

| 48 | 16 | 4 | 4.5 |

|

UI-20 | 60 | 20 | 20 |

| 60 | 20 | 4 | 6 |

|

UI-25 | 75 | 25 | 25 |

| 75 | 25 | 4 | 8 |

|

UI-28 | 84 | 28 | 28 |

| 84 | 28 | 4 | 8 |

|

UI-35 | 105 | 35 | 35 |

| 105 | 35 | 4 | 10 |

|

UI-38* | 114 | 38 | 38 |

| 114 | 38 | 4 | 8 |

|

UI-40* | 120 | 40 | 40 |

| 120 | 40 | 4 | 10 |

|

UI-44* | 132 | 44 | 44 |

| 132 | 44 | 4 | 8 |

|

UI-50 | 150 | 50 | 50 |

| 150 | 50 | 4 | 8 11 |

|

UI-60 | 180 | 60 | 60 |

| 60 | 60 | 4 | 12 |

|

UI-70* | 210 | 70 | 70 |

| 210 | 70 | 4 | 13 |

|

UI-80* | 240 | 80 | 80 |

| 240 | 80 | 4 | 14 |

|

UI-98 | 98 | 30 | 38 |

| 47.5 | 30 | 4 | 8 |

|

UU-13 | 50 | 13 | 24 |

| 21 | 13 |

|

|

|

UI-55(NS)* | 170 | 55 | 60 |

| 180 | 55 | 4 | 12 |

•Marked “*” model is manufactured by manually punch

•Determine core dimensions from transformer specs and winding/bobbin size.

•Choose high stacking factor for maximum winding space and efficiency.

•Opt for low core loss for reduced heat generation and better energy efficiency.

•Optimize core size for desired performance characteristics.

•Consider manufacturing limitations and cost when selecting core size.