EI Core Lamination

EI Core Lamination

EI Core Lamination Features

Scope

Control Transformer

Power Transformer

Ballast Resistor

•Marked “*” model is manufactured by manually punch

•Calculate core area using transformer specifications.

•Choose core size to fit winding and bobbin.

•Minimize air gap for higher magnetic flux density.

•Optimize core size for low core loss and reduced heat generation.

•Consider manufacturing limitations and cost when selecting core size.

FEEDBACK

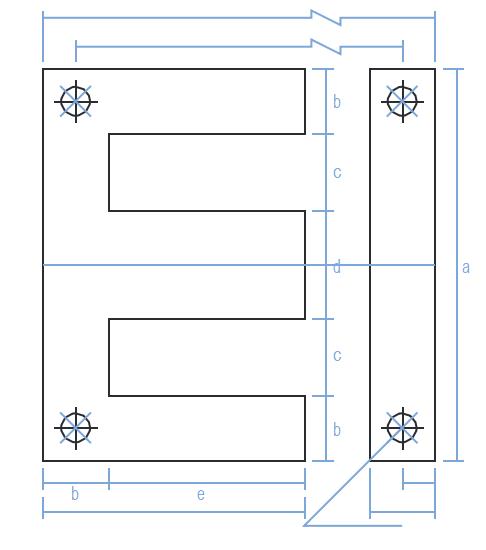

EI Core Lamination Table

| Type | a | b | c | d | e | f | Holes | ø | Gap |

| EI-30 | 30 | 5 | 5 | 10 | 15 | ||||

| EI-35 | 35 | 5 | 7.5 | 10 | 19.5 | ||||

| EI-40 | 40 | 6.65 | 8 | 10.7 | 20.5 | 7 | 2(PH) | ||

| EI-41 | 41 | 6 | 8 | 13 | 21 | ||||

| EI-42 | 42 | 7 | 7 | 14 | 21 | 2 | 3.5 | 0.45 | |

| EI-48 | 48 | 8 | 8 | 16 | 24 | ||||

| EI-48 | 48 | 8 | 8 | 16 | 24 | 2.0 | |||

| EI-48 | 48 | 8 | 8 | 16 | 24 | 2 | 3.5 | ||

| EI-50 | 50 | 8 | 9 | 16 | 25.5 | ||||

| EI-57 | 57 | 9.5 | 9.5 | 19 | 28.5 | ||||

| EI-57 | 57 | 9.5 | 9.5 | 19 | 28.5 | 4(MH) | 4 | ||

| EI-60 | 60 | 10 | 10 | 20 | 30 | 4 | 5 | ||

| EI-66 | 66 | 11 | 11 | 22 | 33 | ||||

| EI-66 | 66 | 11 | 11 | 22 | 33 | 4 | 4 | ||

| EI-66 | 66 | 11 | 11 | 22 | 33 | 4 | 4 | 0.7/0.8/0.9 | |

| EI-67 | 67 | 9.45 | 13.05 | 22 | 4 | 0.7 | |||

| EI-75 | 75 | 12.5 | 12.5 | 25 | 37.5 | 4 | 5 | ||

| EI-76.2 | 76.2 | 12.7 | 12.7 | 25.4 | 38.1 | 4 | 5.5 | fillet | |

| EI-76.2 | 76.2 | 12.7 | 12.7 | 25.4 | 38.1 | 4 | 5 | T=1.0 T=1.4 | |

| EI-78 | 78 | 13 | 13 | 26 | 39 | 4 | 5 | ||

| EI-84 | 84 | 14 | 14 | 28 | 42 | 4 | 6 | ||

| EI-85.8 | 85.8 | 14.3 | 14.3 | 28.6 | 42.9 | 4 | 5 | ||

| EI-85.8 | 85.8 | 14.3 | 14.3 | 28.6 | 42.9 | 4 | 5 | 1.3/1.6/1.8/2.0/1.2/ 1.0/2.4/0.9/0.7 | |

| EI-95.25 | 95.25 | 15.875 | 15.875 | 31.75 | 47.625 | 4 | 5.5 | fillet | |

| EI-96 | 96 | 16 | 16 | 32 | 48 | 4 | 6 | ||

| EI-96 | 96 | 16 | 16 | 32 | 48 | 4 | 6 | 1.0/1.4/2.5/2.7 |

Type | a | b | c | d | e | f | Holes | ø | Gap |

EI-105 | 105 | 17.5 | 17.5 | 35 | 52.5 |

| 4 | 6 |

|

EI-105 | 105 | 17.5 | 17.5 | 35 | 52.5 |

| 4 | 6 | 1.0/1.4/1.6/2.0/2.2/2.8 |

EI-108 | 108 | 18 | 18 | 36 | 54 |

| 4 | 6 |

|

EI-114 | 114 | 19 | 19 | 38 | 57 |

| 4 | 7 |

|

EI-114 | 114 | 19 | 19 | 38 | 57 |

| 4 | 7 | 2.7 |

EI-120 | 120 | 20 | 20 | 40 | 60 |

| 4 | 7 |

|

EI-122 | 122 | 22 | 28 | 22 | 61 | 28 | 4 | 6 |

|

EI-126 | 126 | 21 | 21 | 42 | 63 |

| 4 | 7 |

|

EI-133.2 | 133.2 | 22.2 | 22.2 | 44.4 | 66.6 |

| 4 | 7 |

|

EI-133.2 | 133.2 | 22.2 | 22.2 | 44.4 | 66.6 |

| 4 | 7 | 1.3 |

EI-150 | 150 | 25 | 25 | 50 | 75 |

| 4 | 8 |

|

EI-152.4 | 152.4 | 25.4 | 25.4 | 50.8 | 76.2 |

| 4 | 8 |

|

EI-162 | 162 | 27 | 27 | 54 | 81 |

| 4 | 8 |

|

EI-162 | 162 | 27 | 27 | 54 | 81 |

| 4 | 10 |

|

EI-168 | 168 | 28 | 28 | 56 | 84 |

| 4 | 10 |

|

EI-171 | 171 | 28.5 | 28.5 | 57 | 85.5 |

| 4 | 8(PH) 10 |

|

EI-174* | 174 | 29 | 29 | 58 | 87 |

| 4 | 10.5 |

|

EI-180 | 180 | 30 | 30 | 60 | 90 |

| 4 | 8 |

|

EI-180 | 180 | 30 | 30 | 60 | 90 |

| 4 | 10 |

|

EI-190.5 | 190.5 | 31.75 | 31.75 | 63.5 | 95.25 |

| 4 | 8 |

|

EI-192 | 192 | 32 | 32 | 64 | 96 |

| 4 | 10 |

|

EI-210 | 210 | 35 | 35 | 70 | 105 |

| 4 | 10 |

|

EI-222* | 222 | 37 | 37 | 74 | 111 |

| 4 | 10 |

|

EI-228 | 228 | 38 | 38 | 76 | 114 |

| 4 | 10 |

|

EI-228(PH)* | 228 | 38 | 38 | 76 | 76 |

| 4 | 9.5 |

|

EI-240 | 240 | 40 | 40 | 80 | 120 |

| 4 | 10 |

|

EI-254 | 254 | 48 | 55 | 48 | 164 |

| 4 | 12 |

|

EI-270* | 270 | 45 | 45 | 90 | 135 |

| 4 | 12 |

|

EI-300 | 300 | 50 | 50 | 100 | 150 |

| 4 | 12 |

|

EI-360* | 360 | 60 | 60 | 120 | 180 |

| 4 | 12 |

|

E70(NS)* | 222 | 38 | 38 | 70 | 111 |

| 4 | 10 |

|

EI-28(NS)* | 59 | 14 | 14 | 28 | 45 |

| 4 | 5 |

|

EI-56(NS)* | 200 | 28 | 44 | 56 | 69 |

| 4 | 12 |

|

EI-60(NS)* | 180 | 30 | 30 | 60 | 180 |

| 4 | 10 |

|

EI-150(NS)* | 150 | 25 | 25 | 50 | 95 |

| 4 | 8 |

|

EI-60(NS)* | 210 | 37.5 | 37.5 | 60 | 210 |

| 4 | 10 |

|

EI-162(NS)* | 146.05 | 20.6 | 31.8 | 41.3 | 66.8 |

| 4 | 5.5 |

|

EI-251(NS)* | 228.6 | 31.75 | 50.8 | 63.5 | 139.7 |

| 6 | 9.5 |

|