PROCESS

Manufacturing Process

Manufacturing Process

Centersky offers the customized value-added services to enhance the efficiency and reduce the production process of customers.Centersky helps the customer develop products together and collaborate effictively.

Centersky is working on reducing the iron loss to improve the performance of products. Double Annealing has been widely used in Centersky after numerous tests of R&D team.

Environmental Initiatives

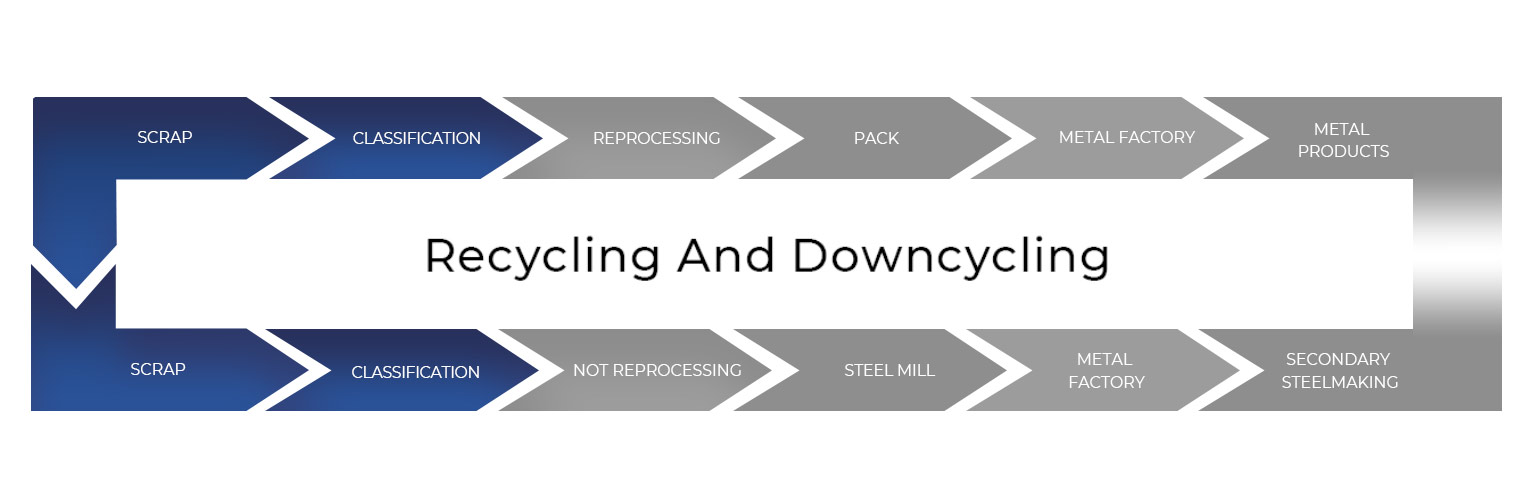

While the steel sector already produces a large portion of its product by recycling scrap metal, additional efficiency in the steel sector supported by its reuse, repair, recycling and downcycling can partially reduce greenhouse gas emissions and help slow the growth of emissions in the industry. To maximise the impact of these circularity measures, some key measures and policies are needed – and in addition to circularity measures, the primary production of steel still needs to be decarbonised.

Recycling and downcycling

referred to as scrap) and iron, the need for which depends on the availability and quality of the steel scrap. Electricity is usually used as a power source in the process and is often complemented with other sources of energy and carbon such as natural gas or coal.

In an Electric Arc Furnace (EAF), at very high temperatures between 1800°C – 3000°C the steel scrap is melted together with iron and some other materials to produce liquid steel. The liquid steel then goes into a metallurgy treatment process. The steel is then cast and formed into the desired shape before it is distributed.

The accumulation of impurities can be improved by better sorting, simpler product design and the development of new technologies for the purification of recycled steel.

According to some scenarios, the current scrap recovery and recycling patterns could lead to a 50% loss of usable steel stock by 2100; it is important to slow this loss of materials through better sorting and recycling practices.

centersky improves design for better sorting and recycling and to ensure longer-lasting products, in combination with improving waste-management practices. Compared with the United Nations Environmental Programme’s recycling statistics, our results show the importance of taking a life-cycle perspective to estimate losses of metals to develop effective circular economy strategies.

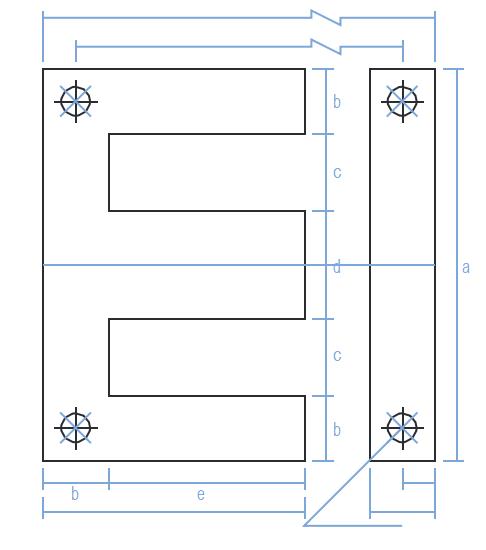

EI Core Lamination Features

Scope

Control Transformer

Power Transformer

Ballast Resistor

FEEDBACK

EI Core Lamination Table

| Type | a | b | c | d | e | f | Holes | ø | Gap |

| EI-30 | 30 | 5 | 5 | 10 | 15 | ||||

| EI-35 | 35 | 5 | 7.5 | 10 | 19.5 | ||||

| EI-40 | 40 | 6.65 | 8 | 10.7 | 20.5 | 7 | 2(PH) | ||

| EI-41 | 41 | 6 | 8 | 13 | 21 | ||||

| EI-42 | 42 | 7 | 7 | 14 | 21 | 2 | 3.5 | 0.45 | |

| EI-48 | 48 | 8 | 8 | 16 | 24 | ||||

| EI-48 | 48 | 8 | 8 | 16 | 24 | 2.0 | |||

| EI-48 | 48 | 8 | 8 | 16 | 24 | 2 | 3.5 | ||

| EI-50 | 50 | 8 | 9 | 16 | 25.5 | ||||

| EI-57 | 57 | 9.5 | 9.5 | 19 | 28.5 | ||||

| EI-57 | 57 | 9.5 | 9.5 | 19 | 28.5 | 4(MH) | 4 | ||

| EI-60 | 60 | 10 | 10 | 20 | 30 | 4 | 5 | ||

| EI-66 | 66 | 11 | 11 | 22 | 33 | ||||

| EI-66 | 66 | 11 | 11 | 22 | 33 | 4 | 4 | ||

| EI-66 | 66 | 11 | 11 | 22 | 33 | 4 | 4 | 0.7/0.8/0.9 | |

| EI-67 | 67 | 9.45 | 13.05 | 22 | 4 | 0.7 | |||

| EI-75 | 75 | 12.5 | 12.5 | 25 | 37.5 | 4 | 5 | ||

| EI-76.2 | 76.2 | 12.7 | 12.7 | 25.4 | 38.1 | 4 | 5.5 | fillet | |

| EI-76.2 | 76.2 | 12.7 | 12.7 | 25.4 | 38.1 | 4 | 5 | T=1.0 T=1.4 | |

| EI-78 | 78 | 13 | 13 | 26 | 39 | 4 | 5 | ||

| EI-84 | 84 | 14 | 14 | 28 | 42 | 4 | 6 | ||

| EI-85.8 | 85.8 | 14.3 | 14.3 | 28.6 | 42.9 | 4 | 5 | ||

| EI-85.8 | 85.8 | 14.3 | 14.3 | 28.6 | 42.9 | 4 | 5 | 1.3/1.6/1.8/2.0/1.2/ 1.0/2.4/0.9/0.7 | |

| EI-95.25 | 95.25 | 15.875 | 15.875 | 31.75 | 47.625 | 4 | 5.5 | fillet | |

| EI-96 | 96 | 16 | 16 | 32 | 48 | 4 | 6 | ||

| EI-96 | 96 | 16 | 16 | 32 | 48 | 4 | 6 | 1.0/1.4/2.5/2.7 |

Type | a | b | c | d | e | f | Holes | ø | Gap |

EI-105 | 105 | 17.5 | 17.5 | 35 | 52.5 |

| 4 | 6 |

|

EI-105 | 105 | 17.5 | 17.5 | 35 | 52.5 |

| 4 | 6 | 1.0/1.4/1.6/2.0/2.2/2.8 |

EI-108 | 108 | 18 | 18 | 36 | 54 |

| 4 | 6 |

|

EI-114 | 114 | 19 | 19 | 38 | 57 |

| 4 | 7 |

|

EI-114 | 114 | 19 | 19 | 38 | 57 |

| 4 | 7 | 2.7 |

EI-120 | 120 | 20 | 20 | 40 | 60 |

| 4 | 7 |

|

EI-122 | 122 | 22 | 28 | 22 | 61 | 28 | 4 | 6 |

|

EI-126 | 126 | 21 | 21 | 42 | 63 |

| 4 | 7 |

|

EI-133.2 | 133.2 | 22.2 | 22.2 | 44.4 | 66.6 |

| 4 | 7 |

|

EI-133.2 | 133.2 | 22.2 | 22.2 | 44.4 | 66.6 |

| 4 | 7 | 1.3 |

EI-150 | 150 | 25 | 25 | 50 | 75 |

| 4 | 8 |

|

EI-152.4 | 152.4 | 25.4 | 25.4 | 50.8 | 76.2 |

| 4 | 8 |

|

EI-162 | 162 | 27 | 27 | 54 | 81 |

| 4 | 8 |

|

EI-162 | 162 | 27 | 27 | 54 | 81 |

| 4 | 10 |

|

EI-168 | 168 | 28 | 28 | 56 | 84 |

| 4 | 10 |

|

EI-171 | 171 | 28.5 | 28.5 | 57 | 85.5 |

| 4 | 8(PH) 10 |

|

EI-174* | 174 | 29 | 29 | 58 | 87 |

| 4 | 10.5 |

|

EI-180 | 180 | 30 | 30 | 60 | 90 |

| 4 | 8 |

|

EI-180 | 180 | 30 | 30 | 60 | 90 |

| 4 | 10 |

|

EI-190.5 | 190.5 | 31.75 | 31.75 | 63.5 | 95.25 |

| 4 | 8 |

|

EI-192 | 192 | 32 | 32 | 64 | 96 |

| 4 | 10 |

|

EI-210 | 210 | 35 | 35 | 70 | 105 |

| 4 | 10 |

|

EI-222* | 222 | 37 | 37 | 74 | 111 |

| 4 | 10 |

|

EI-228 | 228 | 38 | 38 | 76 | 114 |

| 4 | 10 |

|

EI-228(PH)* | 228 | 38 | 38 | 76 | 76 |

| 4 | 9.5 |

|

EI-240 | 240 | 40 | 40 | 80 | 120 |

| 4 | 10 |

|

EI-254 | 254 | 48 | 55 | 48 | 164 |

| 4 | 12 |

|

EI-270* | 270 | 45 | 45 | 90 | 135 |

| 4 | 12 |

|

EI-300 | 300 | 50 | 50 | 100 | 150 |

| 4 | 12 |

|

EI-360* | 360 | 60 | 60 | 120 | 180 |

| 4 | 12 |

|

E70(NS)* | 222 | 38 | 38 | 70 | 111 |

| 4 | 10 |

|

EI-28(NS)* | 59 | 14 | 14 | 28 | 45 |

| 4 | 5 |

|

EI-56(NS)* | 200 | 28 | 44 | 56 | 69 |

| 4 | 12 |

|

EI-60(NS)* | 180 | 30 | 30 | 60 | 180 |

| 4 | 10 |

|

EI-150(NS)* | 150 | 25 | 25 | 50 | 95 |

| 4 | 8 |

|

EI-60(NS)* | 210 | 37.5 | 37.5 | 60 | 210 |

| 4 | 10 |

|

EI-162(NS)* | 146.05 | 20.6 | 31.8 | 41.3 | 66.8 |

| 4 | 5.5 |

|

EI-251(NS)* | 228.6 | 31.75 | 50.8 | 63.5 | 139.7 |

| 6 | 9.5 |

|