In modern industrial society, energy conservation and environmental protection have become the focus of attention. In order to meet the needs of high-efficiency power equipment, silicon steel laminations are widely used in power transformers, motors and generators and other fields. This article will introduce the properties, applications and importance of silicon steel sheets in modern industry.

First, characteristics of silicon steel laminations

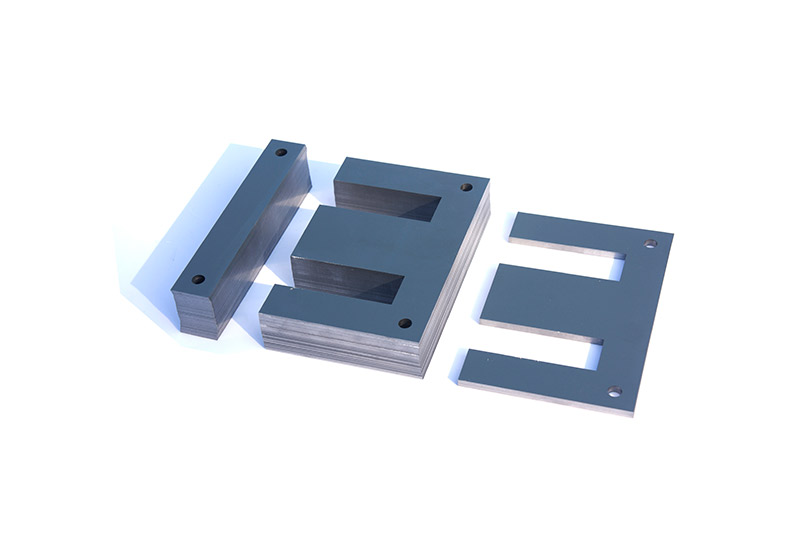

Silicon steel laminations, also known as electrical steel sheet or cold-rolled grain-oriented silicon steel sheet, is a magnetic material with high electrical conductivity and low hysteresis loss. Its characteristics are mainly derived from the optimization of the microstructure. The grain orientation of the silicon steel sheet can make the magnetic flux density conduct better along the material direction, reduce the flux leakage of the magnetic flux, and thus reduce the energy loss.

Second, the application of silicon steel laminations

1. Power transformer: Silicon steel laminations is used to manufacture the iron core of the transformer to reduce the eddy current loss and hysteresis loss in the magnetic field. Higher energy transfer efficiency and lower noise levels can be achieved by using transformers made of silicon steel sheets.

2. Motors and generators: Silicon steel sheets are also widely used in the core parts of motors and generators. Its characteristics of low hysteresis loss and low eddy current loss enable motors and generators to work with higher efficiency and generate less heat and noise during operation.

3. High-efficiency equipment: With the increasing importance of energy conservation and environmental protection, the application of silicon steel sheets in the manufacture of high-efficiency equipment is becoming more and more extensive. For example, silicon steel sheets are used in fields such as air-conditioning compressors, wind turbines, and electric vehicles to improve energy utilization and reduce energy consumption.

Third, the importance of silicon steel laminations in modern industry

1. Energy saving and environmental protection: the application of silicon steel sheets can improve the energy efficiency of power equipment and reduce energy consumption, so as to achieve the goal of energy saving and environmental protection.

2. Noise control: Silicon steel sheets can reduce the noise of electrical equipment, which can improve the living and working environment and improve people’s quality of life.

3. Reliability and durability: The use of silicon steel laminations can improve the reliability and durability of electrical equipment, and reduce equipment failure and maintenance costs. 4. Environmental adaptability: Silicon steel sheet has high temperature stability and corrosion resistance, and is suitable for various harsh working environment conditions.